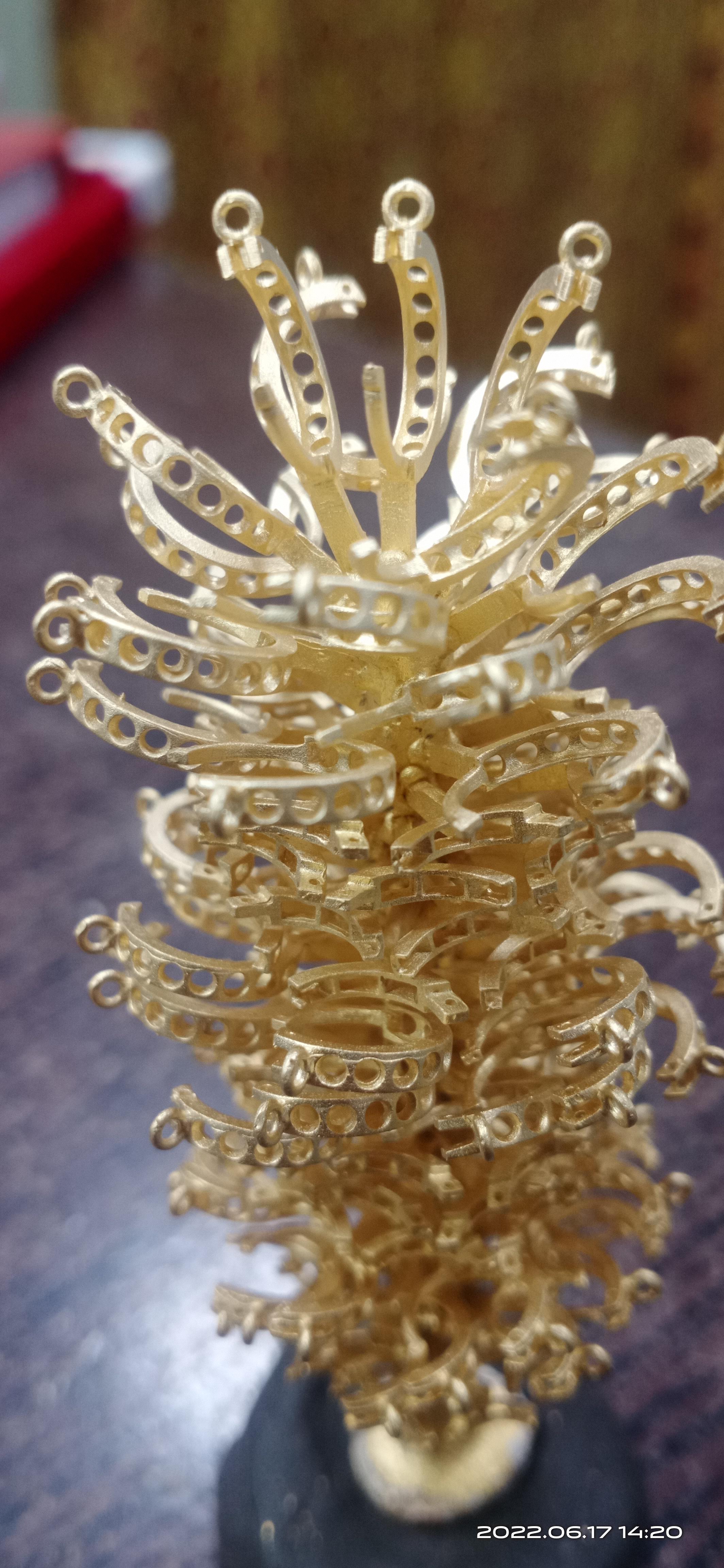

18k gold casting is basic process in jewelry making, but sometime it is very challenging for caster to void certain issue like porosity, cracking or unfiled casting tree. This blog is aims to address some common 18k gold casting problems and provide practical solution to ensure successful and trouble-free casting results.

1.Porosity and Gas Porosity:

Problem: Porosity consider to be tiny air bubble or void within the cast metal, leading to weak spots and rough surface. Gas porosity is often caused by the incomplete removal of gas trapped in flask.

Solution:

2. Cracking:

Problem: Cracking refer as metal brittleness occur due to quench timing.

Solution:

3. Shrinkage and Distortion:

Problem: Shrinkage and distortion can occur due to the solidification of the molten metal, resulting in inaccurate or misshapen casting. This problem mostly happens with bangle or bracelet jewelry.

Solution:

a. Ensure your mold temperature is consistent and optimal for 18k yellow gold.

b. Employ a controlled cooling process to reduce rapid temperature changes and minimize shrinkage.

c. Consider using a casting alloy specifically designed to reduce shrinkage and maintain dimensional stability.

4. Surface Defects:

Problem: Casting defects like surface roughness, pitting, or cracking can mar the final appearance of the jewelry piece.

Solution:

a. Use high-quality, properly maintained crucibles to avoid contamination that can lead to defects.

b. Filter the molten metal to remove impurities and solid particles that can cause defects.

c. Opt for proper burnout cycles to eliminate any residual wax and prevent gas-related defects.

d. Implement a controlled atmosphere or inert gas environment during casting to prevent oxidation and surface defects.

Conclusion:

Casting 18k yellow gold can be a rewarding process when executed correctly. By understanding common casting problems and applying the recommended solutions, jewelry makers can achieve high-quality, defect-free castings that showcase the beauty of this precious metal. Remember that practice, experimentation, and continuous improvement are key to mastering the art of casting 18k yellow gold.